|

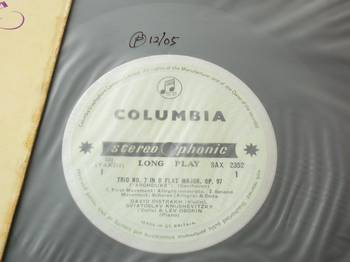

First select a pile of 13 LPs. | |||

|

Place 3 bottles on the

working table.

The bottle should be 3 to 4 inches high. LP placed on its top is very safe as the playable surface is free from any physical contact. |

|||

|

Apply mint solution to the 3 LP surfaces. I always start with the odd number side as a reminder. Use a solid metal weight to stabilize the LP when applying the mint solution. Each single turn of the Loricraft machine last 1.5 minutes. This means each LP surface will be soaked for 3 minutes before their turn. Add a few drops of distilled water if you find the surface has dried up. This avoids over concentration. |

|||

|

Cover the machine top with a 1 mm thick cloth to absorb

the spill over solution. This saves you a lot of hassle.

When the Loricraft is doing its job it needs no attention. Use this time slot to apply mint solution to another LP and attend other details. But observe this priority: always make the Loricraft running by replacing one LP after another immediately. |

|||

|

|

|||

| Cut a piece of PVA rubber for wiping the machine top when necessary. | This rubber helps a lot, I assure you. | |||

|

|

|||

| I like to stack the cleaned LPs for 2 to 3 days. This helps to flatten the warp LP surface. | I choose the Reverse setting for this debris removal run. | |||

|

The cleaned LP must be stored in a brand new inner

sleeve. And box set should be cleaned with a damp cloth.

You may state the date of cleaning on the sleeve for future reference. |

|||